The Beaglebone hardware contains two header connectors, each with 46 pins, 92 pins in total. Just a few are related to special features (such as RESET, GND or power supply lines), while most of them are lines with input / output capabilities, either for analog or digital signals. Some of them are free, others are unfree (used by the system in default configuration). All input / output header pins can get controlled by libpruio, as well as further pins on the J1 header and the SD card slot. Furthermore libpruio can controll internal lines, not wired to any connector (ie. the onboard user leds, example sos demonstrates that).

Analog lines always operate as input. In contrast, digital lines can either operate as input or output, ie. as a simple switch (called general purpose input/output = GPIO). Some digital lines have further features at the same pin, ie. for generating a pulse train. In order to use that features, the pin has to get configured to the matching mode before usage (pinmuxing).

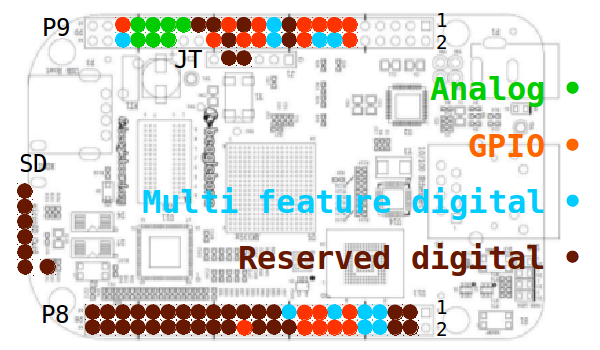

Here's an overview of the Beaglebone Black pins. The settings for other Beaglebone hardware (White, Green, Blue, Pocket-, ...) are different (have more free pins). See the related TRM (technical reference manual) for details.

The pins are sorted into four categories:

For pinmuxing (digital pins category 2 to 4) the connected CPU ball needs to get adressed. Therefor a set of header files are shipped with libpruio, which define the CPU ball numbers by the connectors location. Ie. it's more easy for the user specify P8_07 (pin 7 on header P8) then looking up the related ball number 36 (since the ball numbers are not sorted in any order). Here's a table of the pin headers:

| Name (Type) | Headers | FreeBASIC | C |

|---|---|---|---|

| White, Green, Black | 2x46 headers | src/pruio/pruio_pins.bi | src/c_include/pruio_pins.h |

| PocketBeagle | 2x36 headers | src/pruio/pruio_pins_pocket.bi | src/c_include/pruio_pins_pocket.h |

| Blue | indiv. conn. | src/pruio/pruio_pins_blue.bi | src/c_include/pruio_pins_blue.h |

| ALL Boards | SD card slot | src/pruio/pruio_pins_sd.bi | src/c_include/pruio_pins_sd.h |

For Python programming language all pin defines are included in the binding file src/python/libpruio/pruio.py.

When planing a new project, concentrate on the category 1 to 3 pins, and try to avoid the brown pins. Some of them are used to control the boot sequence and mustn't be connected at boot-time. Others are reserved to be used by the system (ie. for HDMI or MCASP), but they can get freed by re-configurations of the boot sequence, so that you can use them. It's beyond the scope of this documentation to cover all details. Find further information in the SRM (system reference manual) shipped with your board.

BB contains pin specifications for BeagleBone boards while PB contains the similar PocketBeagle board specification.P9_41 and P9_42) are connected to two CPU balls. Both CPU balls must not be set in contrary output states, in order to avoid hardware damages. libpruio handles that internaly, the later configuration overrides the previous.In the first part this chapter explains the different features available on the header pins, and serves detailed information about the hardware limits. In the second part in section Pinmuxing you'll learn how to get a pin in your custom mode.

Analog lines work always as input line. Analog output isn't supported by the Beaglebone hardware (but can get achieved by a combination of a PWM output and a hardware filter).

Analog inputs operate in the range of 0 to 1V8 on Beaglebone hardware. On PocketBeagle boards some pins operate in the range of 0 to 3V3. The header pins are directly connected to the CPU connectors. There's no overvoltage protection, so in order to avoid hardware damages you mustn't trespass the maximum voltage range.

In addition to the seven analog lines available on the header pins (see table below), libpruio can also receive samples from the AIN-7 line, which is internal connected to the board power line (3V3) by a 50/50 voltage divider. This may be useful to measure the on board voltage, in oder to control the power supply.

| BB | PB | Description |

|---|---|---|

| P9_39 | P1_19 | AIN-0 (default configuration in step 1 |

| P9_40 | P1_21 | AIN-1 (default configuration in step 2 |

| P9_37 | P1_23 | AIN-2 (default configuration in step 3 |

| P9_38 | P1_25 | AIN-3 (default configuration in step 4 |

| P9_33 | P1_27 | AIN-4 (default configuration in step 5 |

| P9_36 | P2_35 3V3 | AIN-5 (default configuration in step 6 |

| P9_35 | P1_02 3V3 | AIN-6 (default configuration in step 7 |

| P2_36 | AIN-7 (default configuration in step 8 |

The ADC subsystem samples the input with 12 bit resolution. The minimum input (0V) gets sampled as 0 (zero) and the maximum input (1V8) gets sampled as 4095. In order to make this raw data comparable with other ADC input, libpruio can encode to different bit formats. The default encoding is 16 bit. This means the maximum input of 1V8 gets measured as 65520 (= 4095 * 16).

libpruio provides full control over the ADC subsystem configuration. Up to 16 ADC steps can get configured to switch the required input line, specify individual delay values and maybe apply avaraging. The ADC subsystem supports analog input up to a frequency of 200 kHz. This works for up to eight steps. The maximum frequency for an input line shrinks when

Here's the strategy to fetch analog input (after calling the constructor PruIo::PruIo() )

Find further details on analog lines and the ADC subsystem configurations in ARM Reference Guide, chapter 12. Find example code in io_input.bas, oszi.bas, rb_file.bas, rb_oszi.bas and trigger.bas.

Each digital header pin can get configured either in GPIO mode or in one of up to seven alternative modes. The matrix of the possible connections is hard-coded in the CPU logic. Find the subset of the Beaglebone headers described in the BBB Software Reference Guide, chapter 7. Or find the complete description in the CPU documentation Sitara AM335x ARM Cortex-A8 Microprocessors Guide, chapter 2.2 .

Before a digital header pin gets used, libpruio checks its mode. When the current setting matches the required feature, libpruio just continues and operates the pin. Otherwise it tries to change the pinmuxing appropriately, first. This needs pinmuxing capabilities, see section Pinmuxing for details. Otherwise you've to ensure that all used digital header pins are in the appropriate mode before you start the program (so that the initial checks succeed).

In any case, all digital lines operates in the range of 0 to 3V3. An input pin returns low in the range of 0 to 0V8 and high in the range of 1V8 to 3V3. In the range inbetween the state is undefined. The maximum current on an output pin shouldn't exceed 6 mA.

| Mode | LOW | HIGH | Notice |

|---|---|---|---|

| output | 0 | 3V3 | max. 6 mA |

| input | 0 to 0V8 | 1V8 to 3V3 | undefined from 0V8 to 1V8 |

On BeagleBone boards two of the header pins are connected to multiple CPU balls. Those are P9_41 and P9_42. When changing the pinmuxing of any of the related CPU balls, it must be ensured that the second CPU ball doesn't operate in a contrary output state. You need not care about that, libpruio handles that accordingly.

On PocketBeagle boards there are also double pins, but one of the CPU balls is a AIN input. There is no safety issue here, but you may measure by the analog input some digital output from the connected digital pin.

Depending on the pin mode the pin can act either as input or output pin. Here's the strategy to fetch digital input (after calling the constructor PruIo::PruIo() )

And here's the strategy to set digital output (after calling the constructor PruIo::PruIo() )

GPIO means General Purpose Input or Output. In output mode the program can switch any connected hardware on or off (high=3V3, low=0V). In input mode the program can detect the state of any connected hardware (high>1V8, low<0V8, undefined inbetween). libpruio can configure and use any digital header pin in one of the following five GPIO modes. (Therefor a pinmixing feature has to get activated, find details in section Pinmuxing.) Find details on GPIO hardware in ARM Reference Guide, chapter 25.

| PinMuxing Enumerator | Function | GpioUdt::Value() |

|---|---|---|

| PRUIO_GPIO_OUT0 | output pin low (no resistor) | low=0 |

| PRUIO_GPIO_OUT1 | output pin high (no resistor) | high=1 |

| PRUIO_GPIO_IN | input pin with no resistor | undefined |

| PRUIO_GPIO_IN_0 | input pin with pulldown resistor | low=0 |

| PRUIO_GPIO_IN_1 | input pin with pullup resistor | high=1 |

An input pin can get configured with pullup or pulldown resistor, or none of them. Those resistors (about 10 k) are incorporated in the CPU. In contrast, output pins get always configured with no CPU resistor connection by libpruio (to minimize power consumption). So the first two modes (PRUIO_GPIO_OUT0 and PRUIO_GPIO_OUT1) use the same pinmuxing.

In order to set a GPIO output just set its state by calling function GpioUdt::setValue() (after calling the constructor PruIo::PruIo() ). When you do this after the call to PruIo::config(), the state will change immediately. Otherwise it changes after the PruIo::config() call.

In order to configure a GPIO to input mode first call function GpioUdt::config() (after calling the constructor PruIo::PruIo() and before the call to PruIo::config()). Later (when main loop is running = after the call to PruIo::config() ) check its state by calling function GpioUdt::Value().

libpruio can switch multiple output lines in a single step without any latency between the line transitions. Therefor all related pins have to be controlled by the same GPIO subsystems. See function GpioUdt::flush() for details. The following table shows the pin groups for the subsystems

| Subsystem | Pins |

|---|---|

| GPIO-0 | P8_13, P8_14, P8_17, P8_19, P8_31, P8_32, P8_33, P8_35, P9_11, P9_13, P9_17, P9_18, P9_19, P9_20, P9_21, P9_22, P9_24, P9_26, P9_41, P9_42, SD_10 |

| P1_06, P1_08, P1_10, P1_12, P1_20, P1_26, P1_28, P1_34, P2_03, P2_05, P2_07, P2_09, P2_11, P2_19, P2_29, P2_31, SD_10 | |

| E2_3, E2_4, UT1_3, UT1_4, DSM2_3, GPS_3, GPS_4, SPI1_6, SPI2_6, SD_10 | |

| GPIO-1 | P8_03, P8_04, P8_05, P8_06, P8_11, P8_12, P8_15, P8_16, P8_20, P8_21, P8_22, P8_23, P8_24, P8_25, P8_26, P9_12, P9_14, P9_15, P9_16, P9_23, JT_04, JT_05 |

| P1_30, P1_32, P2_01, P2_02, P2_04, P2_06, P2_08, P2_10, P2_18, P2_22, P2_24, P2_25, P2_27, P2_33 | |

| E3_3, E3_4, E4_3, E4_4, UT0_3, UT0_4, GP0_3, GP0_4 | |

| GPIO-2 | P8_07, P8_08, P8_09, P8_10, P8_18, P8_27, P8_28, P8_29, P8_30, P8_34, P8_36, P8_37, P8_38, P8_39, P8_40, P8_41, P8_42, P8_43, P8_44, P8_45, P8_46, SD_01, SD_02, SD_03, SD_05, SD_07, SD_08 |

| P1_02, P1_04, P1_35, P2_17, P2_20, P2_35, SD_01, SD_02, SD_03, SD_05, SD_07, SD_08 | |

| UT5_3, UT5_4, GP1_5, GP1_6, SD_01, SD_02, SD_03, SD_05, SD_07, SD_08 | |

| GPIO-3 | P9_25, P9_27, P9_28, P9_29, P9_30, P9_31, P9_41, P9_42 |

| P1_29, P1_31, P1_33, P1_36, P2_28, P2_30, P2_32, P2_34 | |

| E1_3, E1_4, GP0_5, GP0_6, GP1_3, GP1_4, SPI1_3, SPI1_4, SPI1_5 |

Find example code in button.bas (input) or sos.bas and stepper.bas (output).

PWM stands for Pulse Width Modulated output. This is generating a digital pulse train with a given frequency and duty cycle. Usualy PWM is used to control actuators, ie. to control the speed of a DC engine, the power of an AC motor, or the position of a servo.

PWM is available on a subset of header pins. A PWM pin is configured as an output pin without resistor connection. This pin gets auto-set to high or low state, depending on a counter running on a certain clock rate. When the counter matches specified values, the state of the output toggles. Since PWM output can get generated by different subsystems (and libpruio supports many of them), the resolution and the frequency range vary between the pins.

| BB | PB | Blue | Subsystem | Frequency Range | Notice BBB |

|---|---|---|---|---|---|

| P8_07 | GP1_5 | TIMER-4 | 0.000010914 to 6e6 Hz | free | |

| P8_09 | P1_28 | TIMER-5 | 0.000010914 to 6e6 Hz | free | |

| P8_10 | P1_26 | TIMER-6 | 0.000010914 to 6e6 Hz | free | |

| P8_08 | P2_28 | GP1_6 | TIMER-7 | 0.000010914 to 6e6 Hz | free |

| P9_22 | P1_08 | GPS_3 | PWMSS-0, PWM A | 0.42 to 50e6 Hz | free |

| P9_21 | P1_10 | GPS_4 | PWMSS-0, PWM B | 0.42 to 50e6 Hz | free |

| P9_31 | P1_36 | SPI1_5 | PWMSS-0, PWM A | 0.42 to 50e6 Hz | MCASP0 |

| P9_29 | P1_33 | SPI1_4 | PWMSS-0, PWM B | 0.42 to 50e6 Hz | MCASP0 |

| P9_14 | P2_01 | PWMSS-1, PWM A | 0.42 to 50e6 Hz | free | |

| P9_16 | PWMSS-1, PWM B | 0.42 to 50e6 Hz | free | ||

| P8_36 | PWMSS-1, PWM A | 0.42 to 50e6 Hz | HDMI | ||

| P8_34 | PWMSS-1, PWM B | 0.42 to 50e6 Hz | HDMI | ||

| P8_19 | PWMSS-2, PWM A | 0.42 to 50e6 Hz | free | ||

| P8_13 | P2_03 | PWMSS-2, PWM B | 0.42 to 50e6 Hz | free | |

| P8_46 | PWMSS-2, PWM A | 0.42 to 50e6 Hz | HDMI | ||

| P8_45 | PWMSS-2, PWM B | 0.42 to 50e6 Hz | HDMI | ||

| P9_42 | SPI2_6 | PWMSS-0, CAP | 0.0233 to 50e6 Hz | free (double pin) | |

| JT_05 | UT0_4 | PWMSS-1, CAP | 0.0233 to 50e6 Hz | JTag (UART0_TXD) | |

| SD_10 | SD_10 | PWMSS-1, CAP | 0.0233 to 50e6 Hz | SD card in button | |

| P9_28 | P2_30 | GP0_6 | PWMSS-2, CAP | 0.0233 to 50e6 Hz | MCASP0 |

The TIMER and PWMSS-CAP subsystems use a 32 bit counter and generate a single pulse train. The signal goes high at the beginning of the period and low when the compare value is reached. In the TIMER subsystems the counter clock can get pre-scaled, so very long periods (low frequencies) are possible. The maximum is 1.06 days.

In contrast the PWMSS-PWM subsystems use a 16 bit counter with 17 bit duty resolution in up-down mode. The frequency range can get extended by a clock pre-scaler. libpruio auto-configures the mode and the pre-scaler. For high frequencies (low counter periods) the counter runs in up-count mode (16 bit resolution). For frequencies below 1526 Hz (= 100e6 / 65536) the counter runs in up-down mode (17 bit duty resolution, 16 bit frequency resolution). This up-down mode can be forced for high frequencies also by masking the subsystems bit in member variable PwmMod::ForceUpDown to 1.

A PWMSS-PWM subsystem handles two outputs at the same frequency. Two Action Qualifiers are used to set the states of the outputs A and B in case of six different events, see ARM Reference Guide, chapter 5.2.4.3 for details. By default libpruio configures the Action Qualifiers to set both outputs to high state at the beginning of a period and switch to low state when the counter matches the duty value. The default configuration can get overriden in array PwmMod::AcCtl. This three dimensional array contains the configurations for the Action Qualifiers.

| Index | Value | Description |

|---|---|---|

| 1 | 0,1 | Output (0 = A, 1 = B) |

| 2 | 0-2 | Subsystem |

| 3 | 0-2 | Usecase (0 = up count, 1 = up count up-down mode, 2 = down count up-down mode) |

Additionally the PWMSS-PWM modules can get synchronized by sending trigger signals from one module to another. Find details in ARM Reference Guide, chapter 15.

The output gets specified by calling function PwmMod::setValue(). Since the output frequency may vary from the specified parameters due to resolution issues, the real values can get computed by calling function PwmMod::Value().

Find example code in pwm_adc.bas or pwm_cap.bas, and the signal geneartor in qep.

A TIMER output is very similar to PWM output, but the pulse train starts in low state for Dur1 duration, and then toggles to high state for the Dur2 period of time. Both durations are specified directly in [mSec] (instead of setting frequency and duty cycle). Additionally a TIMER can operate in one shot mode, stopping after the first pulse, or after a number of pulses in the range of 1 to 255.

The TIMER feature is available on a subset of header pins. By default a TIMER pin is configured as an output pin without resistor connection. This pin toggles its state, depending on a counter running on a certain clock rate. When the counter matches specified values, the state of the output changes. Since TIMER output can get generated by different subsystems (and libpruio supports some of them), the duration range in [mSec] vary between the pins. In any case the counter resolution is 32 bit.

| BB | PB | Blue | Subsystem | Max Dur | Min Dur | Notice |

|---|---|---|---|---|---|---|

| P8_07 | P2_31 | GP1_5 | TIMER-4 | 45812984 | 0.000167 | free |

| P8_09 | P1_28 | TIMER-5 | 45812984 | 0.000167 | free | |

| P8_10 | P1_26 | TIMER-6 | 45812984 | 0.000167 | free | |

| P8_08 | P2_28 | GP1_6 | TIMER-7 | 45812984 | 0.000167 | free |

| P2_27 | TIMER-7 | 45812984 | 0.000167 | free | ||

| P9_42 | SPI2_6 | PWMSS-0, CAP | 42949 | 0.00002 | free | |

| SD_10 | SD_10 | SD_10 | PWMSS-1, CAP | 42949 | 0.00002 | uSD slot |

| JT_05 | UT0_4 | PWMSS-1, CAP | 42949 | 0.00002 | JTag | |

| P9_28 | P2_30 | GP0_6 | PWMSS-2, CAP | 42949 | 0.00002 | free |

The output gets specified by calling function TimerUdt::setValue(). Since the output timing may vary from the specified parameters due to resolution issues, the real values can get computed by calling function TimerUdt::Value().

CAP stands for Capture and Analyse a digital Pulse train. So it means measuring the frequency and the duty cycle of a digital signal input. It's a kind of reverse PWM. Usualy CAP is used to read sensor inputs, ie. from a speed sensor.

CAP is available on a subset of header pins. The specified pin gets configured as input with pulldown resistor. A counter is running on a certain clock rate. Each transition of the input triggers the capture of the counter value. The frequency gets measured as the difference between two positive transitions (a period). The duty cycle gets measured as the ratio between a period and the on-time of the signal. A positive transition resets the couter. Since CAP input can get analysed by different subsystems (and libpruio support some of them), the frequency range vary between the pins.

| BB | PB | Blue | Subsystem | Frequency Range | Notice |

|---|---|---|---|---|---|

| P9_42 | SPI2_6 | PWMSS-0, CAP | 0.0233 to 50e6 Hz | free | |

| SD_10 | SD_10 | SD_10 | PWMSS-1, CAP | 0.0233 to 50e6 Hz | uSD card |

| UT0_4 | PWMSS-1, CAP | 0.0233 to 50e6 Hz | free | ||

| P9_28 | P2_30 | GP0_6 | PWMSS-2, CAP | 0.0233 to 50e6 Hz | free |

| P1_32 | UT0_3 | PWMSS-2, CAP | 0.0233 to 50e6 Hz | free |

The measurement results get available by calling function CapMod::Value(). Before, you have to configure the pin for CAP input by calling function CapMod::config() once.

Find example code in pwm_cap.bas.

QEP stands for Quadrature Encoder Pulse measurement. So it means measuring the position and the speed of a quadrature encoder. Encoders for rotary (ie. for an electrical drive) and linear (ie. for a printer head) movement are supported.

QEP is available on a subset of the header pins. Each of the three PWMSS subsystems contains a QEP module. (The QEP module of PWMSS-2 can get connected on two sets of to the header pins.)

The module can operate in different modes, and depending on the mode it operates on a different set of input signals (header pins). Function QepMod::config() is used to specify the operational mode of the module. It configures one or more header pins, depending on the first parameter Ball. And depending on the mode (and the number of input pins), either

information is available when calling function QepMod::Value(). The accuracy of the position information can get improved by using an index signal that resets the position counter.

| BB | PB | Blue | Type | Subsystem | Measurements | Further Pins | Notice BBB |

|---|---|---|---|---|---|---|---|

| P9_42 | E1_3 | A input | PWMSS-0 | S | free (double pin) | ||

| P9_27 | P2_34 | E1_4 | B input | PWMSS-0 | SDP | P9_42 | free |

| P9_41 | GP0_5 | I input | PWMSS-0 | SDPI | P9_42, P9_27 | free (double pin) | |

| P8_35 | P2_10 | E2_3 | A input | PWMSS-1 | S | HDMI | |

| P8_33 | E2_4 | B input | PWMSS-1 | SDP | P8_35 | HDMI | |

| P8_31 | I input | PWMSS-1 | SDPI | P8_35, P8_33 | HDMI | ||

| P8_12 | P2_42 | E3_3 | A input | PWMSS-2 | S | free | |

| P8_11 | P2_33 | E3_4 | B input | PWMSS-2 | SDP | P8_12 | free |

| P8_16 | P2_22 | E4_3 | I input | PWMSS-2 | SDPI | P8_11, P8_12 | free |

| P8_41 | A input | PWMSS-2 | S | HDMI | |||

| P8_42 | B input | PWMSS-2 | SDP | P8_41 | HDMI | ||

| P8_39 | I input | PWMSS-2 | SDPI | P8_41, P8_42 | HDMI |

Measurements: S = Speed, D = Direction, P = Position, I = Index

Direction information is derived from two different signals that "look" at the sensor lines with a mechanical shift of 1 / 4 of the pitch. So to get direction information at least an B input (or an I input) needs to get specified as Ball parameter to the function QepMod::config().

The speed is defined as the rate of change of position with respect to time v = Δx / ΔT. The QEP modules Capture Unit works at a certain frequency, specified by parameter VHz in the call to function QepMod::config(). At this frequency the current position and the time between the last transitions get stored in the array PwmSS::Raw. Function QepMod::Value() uses these data to compute the speed. By default speed values are scaled in transitions per second. Ie. for a rotary sensor turning at 1 revolution per second you'll get twice the number of lines for an A input and four times the number of lines for a B or I input.

For low speed values transitions period time is used in equation v = n / ΔT, where n is the number of transitions counted (n = 2 for A input, n = 4 for B or I input). The higher the speed value, the smaller the speed resolution. So in contrast, high speed values get computed by counting the number of input transitions in the given period of time (T), using equation v = Δx / T. libpruio auto-switches between both equations and auto-computes the optimal speed value for switching (array QepMod::Prd), in order to get maximum speed resolution.

The speed limits are depending on the hardware in use. Linear sensors don't have an upper speed limit, unless the counter clock rate doesn't get exceeded (100e6 Hz). But in case of a rotary sensor the maximum speed is limited by the number of sensor lines per revolution. When the sensor turns more than one revolution in the measurement period (parameter VHz) the number of transitions (Δx) will be incorrect. So for rotary encoders you've to make sure that the measurement frequency is higher than the maximum sensor frequency, ie. VHz = 25 limits the shaft speed to 1500 rpm (= 25 [1/s] * 60 [s/min]). An alternative approach is to specify a multiple of the sensor lines as parameter PMax and correct the position information accordingly. Parameter Scale can be used to apply a custom scaling factor to speed computations.

The minimum speed is limited by the measurement frequency (VHz). When no transition period (2 transitions for A input, 4 transitions for B or I input) occurs in the measurement time (VHz), the speed gets computed to zero. That's also the case when the direction changes during the measurement period. By default libpruio doesn't count each transition, because time measurement in this case requires high accuracy of the sensor mechanics. If either the duty cycle of a signal is not exactly 50 % or the phase shift between A and B signals is not exactly 1 / 4 (90 °), the computed speed values will change erratic. Since most sensors don't fulfill those requirements, libpruio measures frequency on just one transition of a single signal. This means at least two (in case of A input) or four position counts (in case of B and I input) are necessary to measure a non-zero speed value.

Position information is computed by counting the transitions of the input signals considering the direction information (A and B inputs are necessary). In case of just one input the position counter runs in upwart direction.

An index signal (I input) can be used to reset the counter. By default the counter is set to zero on the positive transition of the index signal when counting in upward direction. And the counter is set to value PMax on the negative transition of the index signal when counting in downward direction.

The measurement results get available by calling function QepMod::Value(). Before, you have to configure the pin(s) for QEP input by calling function QepMod::config() once.

Find example code in qep.bas.

At boot time the operating system sets all pins in a save mode. You can list the default settings by executing the example analyse after power on reset.

When you configure a header pin in your code, libpruio first checks its current mode, and just continues in case of a match. Otherwise action is required to get you what you need. In order to set a header pin in an other mode, or just configure a pull-up or pull-down resistor, there're three methods supported:

Each method has its advantages and downsides. The first two are well known and save, but unflexible. There is no fixed border between them. Ie. you can prepare a mixed device tree blob with multiple settings for some pins, and single settings for the others. Anyway, you have to know and specify each pin configuration before boot. And the necessary tools (device tree compiler, capemgr) are not very reliable. Debugging is a mess. Any change requires rebooting.

In contrast the loadable kernel module (LKM, since version 0.6) is flexible and fast in executation speed. You need not prepare the pins before boot. Instead you can access all pins at runtime, and you can switch any feature at run-time. This method has a short boot time and a small memory footprint. But you can more easy raise conflicts with other systems.

libpruio checks in the constructor PruIo:PruIo() if the LKM is available, and uses it when found. It's the prefered pinmuxing method. Otherwise it checks for settings provided by an universal overlay. If neither of them are present, it works with the current pin settings and throughs error messages when the programm tries to change pinmuxing.

WHILE .DRam[0] > PRUIO_MSG_IO_OK : .WaitCycles += 1 : WEND before the pinmuxing command.A custom setting contains a single configuration for each pin. Once you finished your development and burned the design on a printed circuit board, this is the prefered method for setup.

But this is the final state, and it's a long way to get there.

In order to load a custom overlay, you need to create the device tree blob first. Therefor a source code file (suffix *.dts) is necessary, containing the pin claims and configurations. Also code to export the pins to SysFs is necessary, and the overlay should load the uio_pruss kernel module and enable the PRUSS.

libpruio ships with a tool that can handle all that stuff for you. You specify the bare minimum in a source code file, compile the code and execute the binary. It will create a matching device tree source code, and - when executed with sudo - will also compile the device tree blob to the correct place, so that you can load it as usual (either as uBoot overlay or by capemgr).

Therefor use the source code src/config/dts_custom.bas as a template, rename it and adapt it to your needs, by editing the part

The array named M(...) is of type UBYTE and contains the configuration for the header pins (or CPU balls). This code outputs a file named pruio_custom-00A0.dts in the current directory, ready to get compiled to a device tree blob that

When you execute the binary with sudo, the source code also gets compiled to /lib/firmware/pruio_custom-00A0.dtbo, ready to get loaded from there.

echo pruio_custom > ... in this case (= drop the -00A0.dtbo part).This method is very similar to the previous Custom overlay method. You need source code for a device tree overlay, that gets compiled to a binary blob, which gets loaded by the kernel finally, either as uBoot overlay at boottime, or at runtime by capemgr.

But the source code does not contain only a single cofiguration per pin. Instead the blob prepares multiple configurations for each (or just some) pins, and the mode can get adapted at runtime by SysFs activities. Therefor the programm must be executed with sudo.

libpruio also ships with a tool to generate that kind of device tree blob, named src/config/dts_universal.bas. The same code is used to generate the source file *.dts and compile it. But in contrast the array named M(...) contains multiple configurations for each pin. All standard configurations are prepared in header files, and can get loaded by

' quick & dirty: first create settings for all pins ... #INCLUDE ONCE "P8.bi" #INCLUDE ONCE "P9.bi" #INCLUDE ONCE "JT.bi" #INCLUDE ONCE "SD.bi"

Afterwards you can (and should) reduce the configurations to the set of desired pins. Therefor just empty the entries in array M(...) for the pins your wont use, by code like

M(P8_25) = "" ' #4:BB-BONE-EMMC-2G

All remaining pins will get claimed and configured by the resulting device tree blob, that gets generated after compiling and executing the FreeBASIC code. When executing with sudo, the blob source gets compiled to folder lib/firmware/libpruio-00A0.dtbo, from where it can get loaded by the kernel.

dmesg for errors.This method is pretty similar to the solution used by tool config-pin, but unfortunately it cannot be compatible. While config-pin uses human readable pin naming, libpruio uses byte coding instead. This is feasible since the user need not deal with numbers. Instead he can handle the byte code for pin numbers and modes by the prepared macros. The libpruio code can compute adaptions without containing long lists of text description. The code executes faster, consumes less memory, and is more easy to maintain.

There's another difference. While config-pin allows to set double pins P9_41 and P9_42 in contrary output modes, libpruio handles that pins in a save manner, since there are no P9_91 and P9_92 pins.

Anyway, the desired mode for the pins in use has to be prepared before boot. All prepared modes get loaded at boot time. This increases down boot time and consumes a lot of kernel space memory. Big overlays needs splitting in multiple files.

This method has no restriction to pre-prepared pin configurations. Each pin (or CPU ball) can get configured at runtime to any mode. No device tree overlay with pinctrl-single or bone-pinmux-helper features is necessary at boot time. The LKM features can get enabled (loaded) or disabled (unloaded) at runtime during a session (without re-booting).

You can install the LKM either by the package management system, see chapter Preparation for details. Or you can compile and install it from the GitHub source tree, see section LKM for details. Both methods provide a systemd service named libpruio-lkm.service, which loads the LKM at boot time and makes the pinmuxing feature available for all users of the newly created system group prui (GID < 1000). So when you make yourself a member of that group by executing

sudo adduser <YourUserID> pruio

you can do pinmuxing from user space (without sudo, no administrator privileges necessary).

pruio doesn't get removed when uninstalling. It's still existent after uninstall. To remove it edit the file sudo nano /etc/group and remove the related line pruio:x:... from that file (change is effective after next logout or boot). That way you can also remove a user from that group by deleting only his name in the line. Fancy things may happen when files or folders were created with the ownership of that group.By default, the pinmuxing feature is limited to the free header pins, which are not claimed for other subsystems by the kernel. So you cannot configure pins in default configuration, because all pins are claimed by the cape-universal device tree blob. You can either disable the trigger file by (or by renaming that file, adapt the file name for pocket-beagle, BBGrenn or BBBlue)

sudo rm /boot/dtbs/`uname -r`/am335x-boneblack-uboot-univ.dtb

Or you can disable the libpruio safety feature by calling the constructor PruIo::PruIo() with PRUIO_ACT_FREMUX ored in first parameter.

/sys/kernel/debug. libpruio cannot determin the current kernel claims. For user space pinmuixing you have to disable that feature by seting bit 15 in your constructor PruIo:PruIo() call (parameter Act ored by PRUIO_ACT_FREMUX -> no safety feature).The systemd service handles LKM loading and unloading. You can switch off the LKM at runtime for the current session by executing

sudo systemctl stop libpruio-lkm.service

The service gets stopped for the rest of the session and will start again after next boot. To re-start during the current session execute

sudo systemctl start libpruio-lkm.service

If you don't want auto-loading at boot time execute

sudo systemctl disable libpruio-lkm.service

And to re-enable the boot auto-load execute

sudo systemctl enable libpruio-lkm.service

Allthough it's not necessary, it's still recommended to load a minimal device tree blob along with the LKM, just to claim the used subsystems and set of pins. That way the kernel prohibits other software using that pins and subsystems. The source of such a minimal overlay may get named libpruio-00A0.dts and may look like

Replace the dots by further pins you want to use. But keep in mind, the overlays won't load if you try to reserve pins claimed previously by other systems, ie. like HDMI or MMC. The set of free pins vary on Beaglebone hardware. Find further information in the system reference manual shipped with your board.

Once you finished the overlay source, compile and install it by executing

sudo dtc -@ -I dts -O dtb -o /lib/firmware/libpruio-00A0.dtbo libpruio-00A0.dts

Then load the overlay by the capemgr (add libpruio to file /etc/default/capemgr). In case of trouble check the kernel log output (dmesg | grep uio). (I'm not sure if loading as uBoot overlay in file /boot/uEnv.txt will be also sufficient, the capemgr full sure evaluates the exclusive-use tag.)